Defying

moisture

and

decay,

Boiling

Waterproof

Plywood

stands

firm.

Engineered

to

perform,

it

resists

warping,

swelling,

and

daily

wear.

No

bending,

no

breaking

-

just

endless

performance.

Key Features

Advantages of Choosing Royale Touche BWP Plywood

Superior Waterproofing:

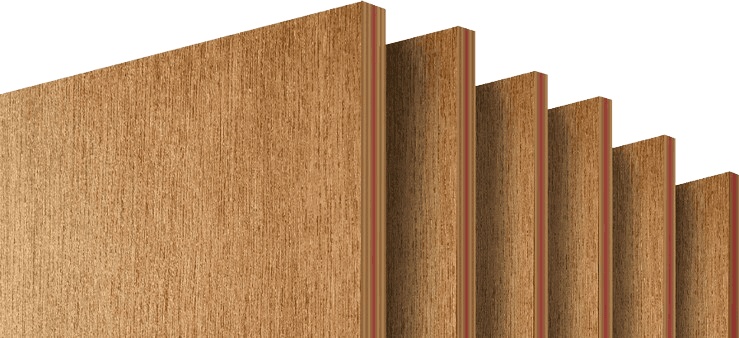

The high-quality resin composition of Royale Touche BWP plywood delivers absolute boiling water resistance. The plywood stands strong against moisture damage regardless of its placement in wet kitchen cupboards or bathroom storage units. Multiple applications can be served by our Boiling Water Proof Plywood which is available as 4mm to 25mm thick panels.

High Strength & Durability:

The exceptional durability of BWP plywood stems from its engineering with numerous hardwood layers of dense composition. The furniture will stay strong due to the structural integrity, which prevents bending or breaking across time. Royale Touche offers the Gurjan-faced BWP plywood variant which provides top-tier strength properties that are best suited for door construction, partition installation and heavy-duty furniture requirements.

Termite & Fungal Resistance:

Anti-termite and anti-fungal treatments given to BWP plywood make it suitable for damp climates. Outdoor applications as well as wardrobes and kitchen cabinets will experience no damage over extended periods when using this material. The manufacturing process includes anti-termite and borer-resistant chemical treatment which ensures extended protection for our plywood products.

Minimal Maintenance:

The maintenance requirements for BWP plywood sheets remain low since the material stays strong while preserving its finish throughout time. The flawless finishing potential of veneers, laminates and natural surfaces results from the smooth surface of the BWP plywood sheet. Royale Touche BWP plywood functions with mica and decorative laminate materials and acrylic sheets to provide finishing flexibility.

Aesthetic Appeal with Versatile Design Options:

The design of our BWP plywood sheets is dedicated to improving interior aesthetics. This product line accommodates various veneers, laminates and textures, which work well for contemporary storage units and sophisticated kitchen cabinetry together with high-end furniture designs. The selection includes wood grain Textures, matte, glossy, as well as textured laminate finishes, which adapt to different interior design preferences.

Applications of BWP Plywood

Kitchen Cabinets & Countertops:

Heat and moisture resistance qualities of this material make it a perfect selection for kitchen cabinets, together with countertops in modular designs.

Bathroom Vanities & Partitions:

Bathroom Vanities and partitions constructed from this material show resistance to constant moisture resulting in prevention of swelling or warping.

Outdoor & Balcony Furniture:

The material withstands rain along with both sun exposure and harsh weather factors to construct durable outdoor and balcony furniture.

Wardrobes & Storage Units:

Long-lasting and resistant to daily wear and tear.

Doors & Windows:

It provides the structural stability to the doors and windows, which also creates an elegant aesthetic effect.

Why Royale Touche?

Royale Touche stands as a premier plywood company which produces premium BWP plywood sheets that exceed all industry quality requirements. Manufacturing at Royale Touche utilizes European technology with advanced quality control to produce highly durable and strong products.

Benefit from Royale Touche BWP plywood systems because they bring you waterproof features alongside durable construction combined with elegant appearances.

Royale Touche Boiling Waterproof Plywood

If you are looking for a plywood solution for spaces at home where there is continuous exposure to moisture and water, then Royale Touche BWP Plywood is what should be considered. This boiling waterproof plywood is designed to withstand extreme weather conditions, exposure to moisture, humidity and comes with long lasting durability. Be it for the bathroom, balconies, terrace gardens or kitchen, the boiling waterproof plywood is apt with guarantee of reliable performance. Choose boiling water-resistant plywood for strength, longevity, and superior resistance to wear and tear.

Why Choose Boiling Waterproof Plywood?

Boiling water proof ply from Royale Touche is best to go for when looking for premium quality, moisture-resistant solutions for the home. Its unique composition makes it ideal for areas where there is constant exposure to water. Resistant to warping and decay, boiling water-resistant plywood is durable without any compromise on aesthetics and elegance. For builders and homeowners seeking reliable protection against moisture, BWP Plywood and boiling water-resistant plywood sheets are the go-to options for unbeatable performance.

FREQUENTLY ASKED QUESTIONS

Q: What is boiling waterproof plywood and how is it made?

A: Boiling waterproof plywood is designed for high moisture and water exposure. It uses a uniquely engineered layered design and high-quality resins. The manufacturing process ensures durability and resistance to boiling temperatures.

Q: What are the main benefits of using boiling waterproof plywood in construction projects?

Superior water resistance maintains functionality in moist environments. Highly resistant to warping and delamination. Provides excellent protection against termite damage.

Q: How does the engineered layered design of boiling waterproof plywood contribute to its durability?

Multiple layers of wood veneers maximize strength and stability. High-quality resins create a robust, durable structure. Cross-laminated layers distribute stress evenly and enhance environmental resistance.

Q: In what applications is boiling waterproof plywood most effective?

Resistance to water and moisture ensures strength and structural integrity, making it suitable for load-bearing applications. Effective in bathroom and kitchen cabinetry due to water and steam exposure. Ideal for outdoor furniture and structures, resisting varying weather conditions. Suitable for marine environments, including boat construction and docks.

Popular Searches

Waterproof Plywood | Marine Plywood | Termite and Borer Proof Plywood | Moisture Resistant Plywood | Fire Retardant Plywood | Wooden Plywood | Veneer Plywood | Calibrated Plywood | E-0 Emission Plywood | Gurjan Face Plywood | Hardwood Plywood | Boiling Waterproof Blockboard | Calibrated Hardwood Blockboard | Pine Blockboard | Blockboard | 6 MM Plywood | 9 MM Plywood | 12 MM Plywood | 16MM Plywood | 19 MM Plywood | 25 MM Plywood

Plywood Applications

Plywood for Furniture | Plywood for Doors | Plywood for Interiors | Plywood for Wardrobes | Plywood for Kitchen | Plywood for Bed | Plywood for Kitchen Cabinets | Plywood for Ceilings | Plywood for Roof | Plywood for Outdoor | Plywood for Shelves | Plywood for Wall Panelling | Plywood for Flush Doors | Plywood for Flooring | Plywood for Shuttering | Plywood for Sofa | Plywood for Partition Wall | Plywood for King | Plywood for Countertop | Plywood for Windows | Plywood for Gate | Plywood for Table Top | Plywood for Dining Table | Plywood for Double Bed | Plywood for Bedroom | Plywood for Queen Size Bed | Plywood for Kitchen Doors

Plywood Design Ideas

Plywood Door Designs | Plywood Bed Designs | Plywood Mandir Designs | Plywood Almirah Designs | Plywood Ceiling Designs | Plywood Kitchen Designs | Plywood Sofa Designs | Plywood Table Designs | Plywood Gate Designs | Plywood Wall Designs | Plywood Chair Designs | Plywood Singhasan Designs | Plywood Study Table Designs | Plywood Dining Table Designs | Plywood TV Unit Designs | Plywood Double Door Designs | Plywood Window Designs | Single Ply Door Designs | Plywood Shoe Rack Designs | Plywood Partition Designs | Plywood Showcase Designs | Plywood Box Bed Designs | Plywood Dressing Table Designs | Plywood Computer Table Designs | Plywood Folding Table Designs | Plywood Office Table Designs | Plywood Main Door Designs | Plywood Arch Designs | Plywood Jali Door Designs | Plywood Coffee Table Designs | Plywood Wall Interior Designs | Plywood Double Bed Designs

Cities in We are Present

Plywood in Bangalore | Plywood in Delhi | Plywood in Ahmedabad | Plywood in Hyderabad | Plywood in Chennai | Plywood in Pune| Plywood in Raipur | Plywood in Kolkata | Plywood in Noida | Plywood in Indore | Plywood in Lucknow | Plywood in Ghaziabad | Plywood in Ludhiana | Plywood in Kanpur | Plywood in Gurugram | Plywood in Bhopal | Plywood in Jaipur | Plywood in Vadodara | Plywood in Nagpur | Plywood in Kochi | Plywood in Bhubaneswar | Plywood in Rajkot